| THICKNESS (IN MM) | 0.15 To 1.20 |

|---|---|

| WIDTH (IN MM) | 750 To 1500 |

| COIL FORM | PPGI / PPGL / BGL / PPAL / AL / GI / GP / CRC / HR |

| STANDARD | A 755 / EN 10169 / IS 15965 / IS 14246 / AS 2728 / JIS G 3322 / IS 1254: 1991 |

| COLOR COAT TOP | RMP / SDP / SMP / PVDF / PVC / HSDR / PU / EPOXY = Up To 45 Micron |

| COLOR COAT BACK | Epoxy = Light Grey Color Standard = Up To 15 Micron |

| GUARD FILM | Optional |

| TENSILE STRENGTH | Up To 550 Mpa |

| HARDNESS | 55 To 65 HRB |

| COIL WEIGHT | 3 To 6 MT |

| CHEM.COM.&MECH.PROP. | Test Certificate Available |

| BASE MATERIALS | PPGI / PPGL / BGL |

| B M COATING (IN GSM) | PPGI = Z 70 / Z 90 / Z 120 / Z 150 / Z 275 |

| B M COATING (IN GSM) | PPGL = AZ 40 / AZ 70 / AZ 90 / AZ 150 |

| B M COATING (IN GSM) | BGL = AZ 150 |

| COLOR OPTION | White / Blue / Green / Red / Grey / Print / Option RAL Color Chart |

| BRAND | Steelcoat / Asian / JSW / Jindal / Essar / Coloshine / Tata BSL / National / Manaksia / Imported |

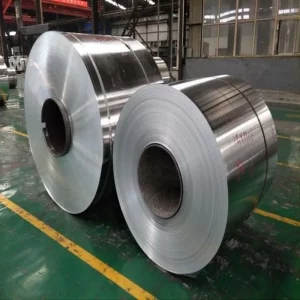

Color Coated Coil PPGI PPGL BGL

Pre-Painted Galvanized Steel Coils & Pre-Painted Galvalume Steel Coils are widely used for industrial, commercial and residential roofing and cladding, interiors, false ceiling, door framing, factory shades, warehouses, cold storages and appliances.

You haven't viewed at any of the products yet.

Related products

Email :

info@hitechindustries.co.in

phone :

+91 8000035000